For two months, we worked to find a fuel problem on our boat. Several times, we thought perhaps we’d solved the problem and then when we’d try to motor, we’d find we still had a problem.

Finally, our last fix seems to have done it. We’ve run the engine over 20 hours since then without even a hiccup.

Symptoms and Possible Causes

The engine would run fine, then lose RPMs . . . and then come right back . . . and then would lose more . . . and so on, eventually dying. The Westerbeke has an electric fuel pump on it, and if we did the bleed procedure — 30 to 60 seconds of pumping the fuel — it would start again and run well . . . for a while. Then the ups and downs would start again.

Everyone we talked to and all the books we read agreed that the basic problem was fuel starvation. But why? It could be dirty fuel and a plugged filter, a problem in the fuel pickup tube in the tank, water in the fuel that was getting past the Racor, an air leak or even a kinked or collapsed fuel hose.

Finding the Cause of a Fuel Problem on a Boat

We began with the simple, more common problems and then progressed to checking other things that would cause a fuel problem on a boat:

- Our Racor hadn’t seemed dirty, but we started by changing all the fuel filters. No improvement.

- We had no water whatsoever in the Racor, so ruled that out.

- We then pumped all the diesel out of one tank, pulled the tank out and cleaned the inside of it, reinstalled it, then ran the fuel back into it through a Baja filter (no significant water or crud). We knew we had clean fuel and a clean tank. The pickup tube was permanently installed (we called the tank manufacturer to confirm this) so we did not remove it to check it for blockages or cracks. Our fuel polishing made no difference.

- Some Westerbeke literature said we should use a 2 micron Racor, others a 30 micron. We called Westerbeke tech support and they said to use a 30 micron if we were having fuel starvation issues. We got one. Initial testing showed that the engine was now running well, so we went ahead and made a trip to Key West to visit friends vacationing there. Just as we got into the big ship channel there, we had some RPM dips. The problems got much worse on the return to Marathon with the engine dying several times.

- Since we’d had more problems as the trip had progressed and thus there was less fuel in the tank, we suspected maybe there was a crack in the tank pickup. We did some more reading on the Tempo fuel tanks that we have and found that (a) a crack in the pickup tube is a semi-common problem and (b) someone had cut off the “permanent” fitting, fixed the cracked pickup, and then reinstalled it. Dave again pumped all the fuel out of the tank and pulled it. He discovered he could get the fitting off by heating the plastic with a hairdryer. Our pickup tube was not cracked or blocked. He replaced the tank.

- Looking at our fuel hoses, it seemed impossible that there was a collapsed or kinked hose. Thus we decided to concentrate on an air leak.

- We knew that the leak had to be somewhere between the tank and the fuel pump. This is where the fuel is being sucked and air can be sucked in anywhere that isn’t tightly sealed off. After the fuel pump, the fuel is under pressure and will seep out any unsealed areas as a fuel leak. That’s also a problem, but won’t produce the symptoms we had of an engine losing RPMs and dying.

- We’d already ruled out a crack in the pickup tube in the tank.

- Nigel Calder recommended using the clear bottom of the Racor bowl as a sight glass to see if a leak was before/in the Racor system or after it. Simply put, any bubbles in the bowl as fuel is pumped (either through a bleed procedure or as the engine is running) means the leak is before or in the Racor, and no bubbles means the leak is after. I practically stood on my head to look at the Racor bowl while Dave ran the electric fuel pump: every once in a while (30 seconds, maybe?) I’d see a tiny, tiny bubble. About half the size of the head of a pin, but all three diesel books said that even the slightest bit of air would cause problems. Ah-ha! We had a leak somewhere between the tank and the Racor exit.

- Dave traced the fuel hose and looked at all the components. He tried to tighten every hose clamp. We have two fuel tanks and valves that determine which tank is being used and returned to. The valve stems seemed a little wobbly and we called the company’s tech support to see if this would let air in. They said yes, so we bought two new valves. When Dave replaced them, the new ones seemed to have as much play as the old ones. Sigh.

- In changing the valves, Dave had to remove our dual Racor assembly. He checked it over thoroughly for any loose connections and — lo and behold! — found that one of the unused port plugs had never been screwed in all the way, let alone had any thread sealant used on it. He fixed that, and we were confident that we had the problem licked.

- We bled the fuel system and started the engine up while still on the mooring, and it died almost immediately. Big sigh.

- I looked at the Racor bowl some more and did not see any bubbles when Dave ran the fuel pump. So now we figured that we had another air leak between the Racor and the fuel pump. There are two fittings, two hose clamps and one hose between the two.

- I started looking at the hose very, very closely, lying on the deck with my head inside the engine compartment. I ran my fingers down the hose and could feel just a tiny “imperfection” next to the hose clamp by the fuel pump.

- It really didn’t seem to be anything, but as it was the only thing we could find, Dave decided to remove the hose and replace it.

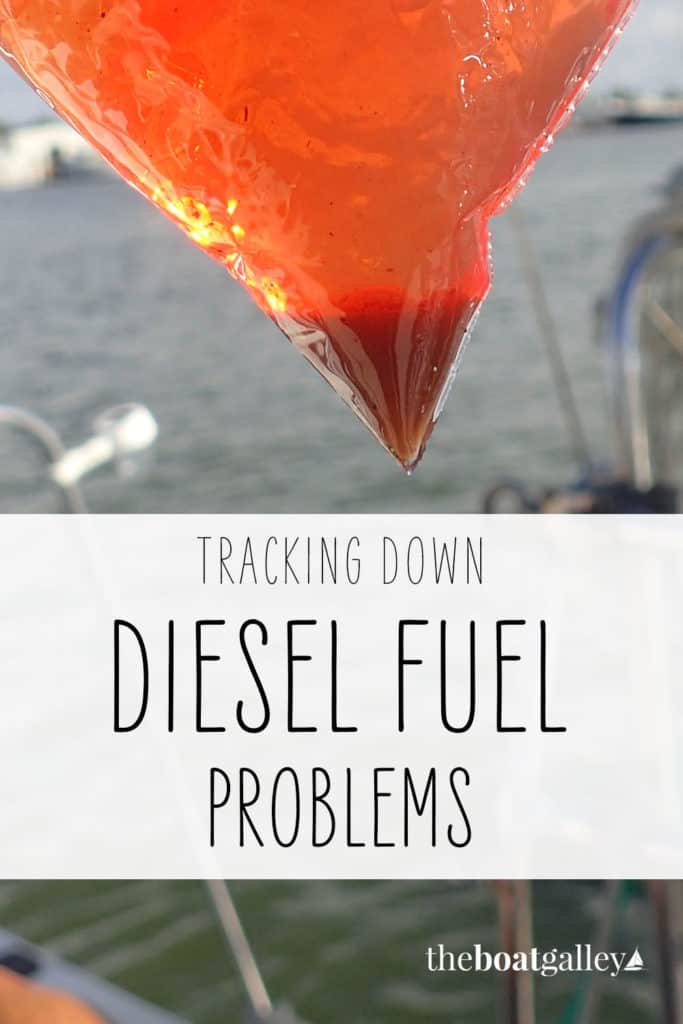

- When he took the old hose out, we could spot a tiny crack in it. And I do mean tiny. It was easier to see when I bent the hose a bit.

Finally, when we started the engine it ran well. We took the boat out and motored for over 3 hours in 2 to 3 foot waves. We toasted finally tracking the problem down.

The next day, we went out sailing “just for fun.” Not testing anything. Just having a wonderful time.

And as we started up the engine to come back in the harbor, it died. But it started right up again . . . and hasn’t quit again (or had even the tiniest RPM drop) in over 20 hours of motoring. All we can figure is that there was one last bit of air, maybe trapped in a high spot, that dislodged. We’re now declaring the problem solved.

Lessons Learned

The lessons that we took away from finding this fuel problem:

- Tracking down air leaks is tough and can take a long time. If you hire someone, it’s going to be expensive. It really doesn’t take any special skills, just patience.

- Using the Racor bowl as a sight glass is a great way to figure out if the air leak is before (or in) the Racor or after.

- There may be more than one leak.

- If someone else on board has better close-up vision or more sensitive fingers for finding imperfections, get them involved. No mechanical knowledge needed. Sometimes, it’s someone who isn’t familiar with the system who says “is this supposed to be like this?”

- Check all fittings and connections . . . including the “dead ends” as in our Racor.

- The problem area(s) are likely to appear almost insignificant. And they may be on the “hidden” side of hoses.

- Perseverence.

Read Next

Carolyn Shearlock has lived aboard full-time for 17 years, splitting her time between a Tayana 37 monohull and a Gemini 105 catamaran. She’s cruised over 14,000 miles, from Pacific Mexico and Central America to Florida and the Bahamas, gaining firsthand experience with the joys and challenges of life on the water.

Through The Boat Galley, Carolyn has helped thousands of people explore, prepare for, and enjoy life afloat. She shares her expertise as an instructor at Cruisers University, in leading boating publications, and through her bestselling book, The Boat Galley Cookbook. She is passionate about helping others embark on their liveaboard journey—making life on the water simpler, safer, and more enjoyable.

Your VHF can do so much! Learn how to use ALL its features for just $39:

Mike B. says

Having recently played this game myself…and met with only semi-success…I can really appreciate what you went through. And patience IS a skill. 😉 Good job on tracking it down.

-Mike

ThisRatSailed

Marc Focke says

Jan Pieter Eskens

Carole Erdman Grant says

The cute dog looks like she is very interested in those tools!

The Boat Galley says

Well, I didn’t want to say anything, but really she was the one who told us what to look for . . .

Victor says

She knows how to sniff out the problems.

Kim zimmer says

thanks so much for posting the details of your troubleshooting. I’m pinning this for future ref

Drench!

Jimmie White says

I chased a fuel delivery problem from Mobile all the way to Nassau. It would only show up on the starboard tank after motoring for five or more hours at 2400 rpms or more. Turned out to be a restriction in the stainless screen at the top of the pick up tube. It was hidden from view and I only found it by accident.

It certainly is a relief to figure these kind of things out after so long a time.

The Boat Galley says

Glad you finally found it. Such a pain when it doesn’t show up “all the time.”

Mike McCollough says

Very methodical work! If everything around you looks true, you checked more than once, then the problem is in any earlier assumption.

There was a guy whose Porsche would not start intermittently. The problem took over a year to determine the source. His girlfriend would top off the oil, certain Porsches would leak, with a detergent oil. When enough detergent oil was in the system it would foam up and foul the injectors. By the time the car was taken to the shop the foam would subside and the engine would start.

In older cars cracked hoses were a common source for vacuum leaks, cracks as fine as the one you have.

Congratulations on a job well worked.

ChrisW says

For seeing what is going on in really hard to get to places, we use a USB web cam and watch via the lap top screen. This also has the advantage of allowing zoom. I have actually done work on hard to reach items using this approach.

Glad you got past this.

Also one completely different item — what is your mast head clearance?

Gimme Shelter says

Glad you solved it!

Cathleen Speaker Holzknecht says

Dave Holzknecht

Kristine Henson says

Thanks! Useful information!

Bruce Comeau says

I would have replaced the fuel lines first. All of them. After owning 11 boats, one thing I learned is if there is a hint of fuel problems I replace all the lines.

Bart Trish Masker says

Perseverance pays off. Good for you! 🙂 Did I miss why you are back on the hard?

Carolyn Shearlock says

To sell our house this summer so we can cruise full time 🙂

Kym Dutfield-Cooke says

Thankyou for posting this – we were just about to start trying to diagnose a similar issue. We thought we had a fuel blockage, but after reading this rushed to check our racor for bubbles. We had bubbles galore! Found a loose hoseclamp and no more bubbles ☺ and engine is running like a dream. Now just hope that was the only problem, fingers crossed.

Carolyn Shearlock says

Hope it’s solved!

lex says

thanks for the informative and detailed article. This publication is right there in the trenches (bilges?) with the rest of us boaters, and has many good tips and explanations.

The Sea and Sailors says

🙂

Norris says

Hello guys,

I just bought a 97 baja hammer and it seem to be having the same issue.

Runs for 15mins and loses RPM then later dies.

I will wait for a few mins and retart engine, then have to go thru the issue again.

Changed duel filter no luck, I’m not a very handy a person. So I will need someone to walk me through the diagnosis steps. Very frustrated.

Thanks

Carolyn Shearlock says

I totally understand the frustration — we had it in spades. It takes a lot of patience to track down the source of this type of problem, and the prroblem will probably turn out to be something really tiny and hard to see.

norris says

Just wondering if someone can walk me thru how to remove pickup tube from my gas tank.

This is the second step of my fuel problem diagnostics.

Thanks

Carolyn Shearlock says

Ours supposedly couldn’t be taken apart. We found some stories of people cutting them and all sorts of stuff. The answer was much simpler: use a hair dryer to warm the fitting up, then pull with Visegrips (NOTE: ours was diesel, not gas, so far less risk of an explosion with a hair dryer and heat. Not sure if I’d use a hair dryer around gas — find a non-sparky way to heat it.)

It’s hard to see the pickup tube in the photo as it’s black, but it’s attached to that metal piece that the Visegrips are pulling out.

Norris says

Thanks Carolyn, looks too risky for me to play with though.

Brian says

Thanks for the photo, I literally ran into this issue this week trying to diagnose the same exact problem.

Candy Ann Williams says

Great article….thanks for sharing…air leaks like that can be unbelievably frustrating! I KNOW you guys must be relieved!!

Raquel Hernandez says

Brian Liddy

Joysealife.com says

Just read your shutting off the water pump while traveling article and then last time out – – case of the missing water. 250 gallons and we never saw it leave the boat. Luckily we were planning to go home that day anyway. Still it’s a mystery. We’ve been checking for leaks.

The Boat Galley says

Depending on how you were heeled, it can siphon out. Happened when we were on a friend’s boat. Luckily there was a water dock right by where we had anchored!

Heather Kolankowski says

The biggest thing with Racor filters is they MUST be filled to the brim. The manufacturer says the filters need only be half full.. This is not true and after years of engine failures, always when the conditions have the boat bouncing all over, we sorted this out with the help of a fellow mariner who had the same filters and problems. We haven’t had even a sputter since and our crossing of Hecate Strait was horrible (weather forecast calm seas and no wind hahaha). All other maintenance is equally important and if you’re using Racor fill them up.

Hugs and Fishes from Haida Gwaii,

Heather Kolankowski

Mike Sweeney says

Good post!

Ted Faber says

On gas engines you can use WD 40 to find leaks. If there is a leak the engine will speed up. Question where do you purchase parts. I just purchase a zine pencil and two switches one for the glow plug and starter switch. Anyway I purchase the parts from a local Westerbeke dealer. The shipping was $ 48. I’m in the same state has the dealer. The dealer tack on the shipping cost Westerbeke charge the dealer. So I would like to find another source

The Boat Galley says

We have been using Carp Coastal and they’ve been pretty good . Not sure if they send outside Florida however.

Ted Faber says

Thanks I will check

The Boat Galley says

Oh, and you can get the pencil zincs at West Marine or any marine store.

Pamela Douglas Webster says

Just wanted to thank you for writing this post last year.

When we were struggling with a hard to diagnose fuel problem on our new-to-us boat, I read this carefully. It convinced us to hunker down and replace all the fuel line before setting off rather than to spend months trying to spot something that could be as tiny as your cracked hose was.

It worked and we’ve had no problems since. So thanks!

The Boat Galley says

I think that would have been and easier way to do it.

Pamela Douglas Webster says

The Boat Galley We definitely would have floundered longer if we didn’t have an example of a crew with far more experience than we had still struggling. So thanks.

Heather Kolankowski says

We have a dirty fuel issue in the port tank. My husband has done everything. We are unable to access the tank much less remove it for cleaning (short of literally destroying the galley and salon) which is the problem. The first batch of fuel has been disposed of, the second batch polished twice. How do we get the tank clean when it has baffles trapping the last bits of crude?.

As of now we carry a lot of filters! Of course the engine dies in the worst and waviest conditions when the crud gets stirred up. Luckily for us good old starboard is our “go to girl”. Not only is this problem annoying but also dangerous in rough seas. Suggestions please?

Carolyn Shearlock says

That’s a problem with a lot of boats with baffled tanks.

Some polishing services do steam cleaning of tanks, but we have never had it done so I don’t know if it can get crud from behind baffles. I’ve read that many services use a pressure washer with special tips to get to otherwise inaccessible areas — the trick of course being not to damage the tank with too much pressure.

I also recall reading where someone put a longish metal tube onto a hose attached to a pump, and kept sucking out the bottom of the tanks, periodically adding more (filtered) fuel to stir up the crud on the bottom enough that it would get sucked up.

We once did something similar with a non-baffled tank that had gotten 10+ gallons of water put into it by mistake, but simply pulled the fuel line apart at a connector and let the fuel/water free flow into a bucket in the bilge (the bucket has to be below the tank level since it’s just a gravity feed). The first buckets were mostly water and discarded in the fuel dump; later buckets we filtered and reused the good stuff.

Yes, it’s a serious safety issue in addition to being a pain!

Scott Carpenter says

Wish I had this to read two years ago when I had a similar problem.

Bob Ellett says

The easiest way to isolate an air leak is to place segments of clear plastic flue line segments in the line between tank and the engine fuel pump. Run the engine fast, look for air bubbles in the areas of line. Clear fuel lines are available for gasoline engines and diesel does not seem to affect the lines for short term, investigative use.

Dave says

Thanks for “reposting” this Carolyn…….we are literally right in the middle of sorting through this problem. Fortunately I have my wife to periodically talk me off the ceiling!! Clearly a problem that calls for more patience that technical know how.

Carolyn Shearlock says

Oh, it is SOOOO frustrating. Good luck!

Bob Ellett says

I had the same problem with engine rpm and air leak onto the fuel. I used segments of clear fuel tubing at multiple line junctions and ran the engine at high RPM. You could actually see large volumes of air bubbles in the fuel thereby isolating the location of the leak. It turned out to be in copper tubing under the sole.

Pamela Douglas Webster says

I so appreciated this post. When we had problems with our engine cutting out two years ago, your story convinced us to immediately replace all the fuel lines. It was probably time anyway and it seemed to make more sense to just do it and not go line by line looking for the problem.

Learning from your experience helped us save hours of frustration.

The Boat Galley says

Glad to hear that. I always hope that what I write will help someone else — no reason for us all to learn the hard way!

David E. Bell says

not forgetting the pickup tube inside the tank, for those of us who have top feed tanks.

The Boat Galley says

David E. Bell Yep, that was a pain to get out and turned out to be perfectly good. Actually, it was pretty easy to remove. The pain was figuring out HOW to.

Travis Weaver says

Currently a marine diesel mechanic in Sausalito/bay area, .CA, for the last 5 years, 9 times out of ten if you do regular engine bleeding and it doesn’t solve the problem, go to the injectors. Had this problem last week, tracing fuel lines, looking at filters, connections, pumps, etc… then I went to the injectors, noticed 3 out of 4 of studs on the return line didn’t have washers…they were so tiny, but as soon as they were replaced, the engine ran great. It’s remarkable how tiny a leak can be to completely decomission an engine. Glad yours is still running, can’t wait to get cruising myself and get out there to help people with their engine problems so they can get going and enjoy their time faster.

The Boat Galley says

Funny you mention that. Just last week a friend had a problem and that’s exactly what it turned out to be.

Don Frank says

Good article, – recently just went through a weird fuel leak myself. My port Cummins (480HO/ 5.9 litre 2012) developed a small fuel leak (3 oz) after running out on the Ohio River. Each time I’d clean I off the bilge floor and next time after running it the fuel would be back on the floor. Cummins traced it to a very small crack in the Fuel Injection Pump which requires complete replacement of the pump. I did try and argue out that it should not have failed in only 492 hours, but they didn’t agree. Soo 2300 bucks later, it’s fixed. I will say that the Cummins folks here in Cincinnati (Cummins West Chester) were awesome, going from diagnosis to repaired in 4 days, and the Tech (Shane) even re-sprayed the area with Cummins White paint so it looks brand new. Small cracks are tough to find, but definitely cause issues that are easy to notice lol….

John Barltrop says

There is such a thing called preventive maintenance and no doubt with all equipment on board a vessel you should have the respective manufacturer’s manuals and they will always have a preventive maintenance schedule include……..and of course they should be followed at the recommended intervals.

One of the main causes of fire aboard vessels is associated with flexible fuel lines……….your fuel lines were an accident waiting to happen, you were fortunate they only caused your engine to run like a “hairy goat”…………it could have been a lot worse, if you had had an engineroom fire……..and I do not mean just the loss of a vessel.

Another major cause of fire are ill maintained vessel’s electrical systems. Once a vessels gets to 3-4 years old insulation tests should be carried out on the entire electrical on an annual basis due to vibrations and buffeting vessels undergo when at sea.

Ronald Harbin says

I had a similar problem on my Islander 30. I was getting air in the fuel. The engine failed more and more frequently. In the end, I drained all the fuel out of the lines and connected a bicycle pump to the system. I pressurized it slightly with air and did a bubble test. What I found was lots of soap bubbles coming out of the banjo fitting on the inlet to the fuel pump. The fitting had been missing the small copper washer that all banjo fittings are supposed to have. I know it was missing since before I had purchased the boat a year or two before but it just never leaked – till now. I purchased a 20 cent washer,installed it, filled the system back up with fuel and never had a problem again.

Jerry Neal Slayton says

Thanks Carolyn, I have been fighting the same problem for a year with the Yanmar 30GM losing several hundred rpms when running over 2000 rpms and then catch up again after a few seconds. Much later the engine dies. Bleed it at the injector pump and it runs fine until the next time I push it over 2000. I have checked over the system but not as closely as you make clear is needed.

I thought your site might be good only for cabin and galley issues never thinking that you could address an engine problem that I have not been able to find online.. Thanks again, Jerry

Rhon Nelson says

What valuable, hard-won information you give us to use if we ever need it. Thanks so much for the detailed, extensive descriptions of your trouble -shooting. Excellent!

Dan says

I had the very same issues of fuel starvation and the problem was the Racor assembly. But, there were no bubbles, no leaks at fittings, it even passed a vacuum test. How did I find it? I bypassed it putting a $6 outboard plastic filter inline between the input and output hoses. I’ve run all summer this way and will address replacing the Racor at season end. The important lesson is to absolutely isolate the problem. Replacing things based on guesswork is always more expensive and usually not productive.