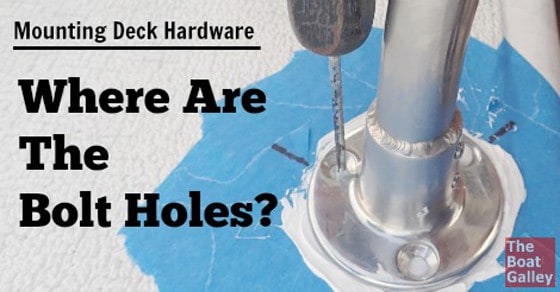

If you’ve ever rebedded deck hardware or installed something new, you know what a pain it can be to get the bolt/screw holes lined up.

The typical scenario is that you dry mount the item, drill any new holes necessary, tape around the hardware, remove the hardware, clean the area with solvent, slather on the sealant, put the item back in place . . . and then try to get it lined up exactly as it was before and find the bolt holes to actually mount it.

You want to get it mounted and the tape — with the excess sealant — off as quickly as possible so that you get a nice clean tape line and nothing sticking where it shouldn’t. And since you know time is of the essence, it’s impossible to get everything lined up quickly. It’s even worse when you have a circular mount, such as that in the photo, where there’s no obvious “this way up.”

We’ve discovered two things to make the process easier. First, when we dry mount the item, we use a Sharpie (permanent marker) to make some guide marks on the tape far enough away from the mounting area that the sealant isn’t likely to ooze and cover them up.

We mark all the holes and anything else that might help us get things lined up quickly again.

And then when we’re getting things lined up after the sealant has been applied, we use an ice pick to find the holes. Long, thin and pointed, it’s much easier than just trying to put the bolt in and wiggle it around until its exactly lined up. We’ll do one of two things depending on which seems to work best in a given situation:

- Put the ice pick in one hole and get it perfectly lined up, then carefully remove it and put the bolt in the hole we just lined up; or

- Leave the ice pick in place and put one of the other bolts in.

Sometimes one technique works best, sometimes the other. By the way, we use an ice pick on lots of other “screw” projects to line holes up. It’s one of the great tools on the boat!

Your VHF can do so much! Learn how to use ALL its features for just $39:

Lauri Cawthon says

Excellent!

Jonathan says

wow, taping, total waste of time, solvent cleans the excess up in a jiffy.

Andrew says

I just put in wooden toothpicks. Drop the hardware over the pick and then pull the toothpicks one at a time as I put in the screws. Easy Peezy.

michele says

Yep, I tried that too in my door knob but so little room for error I keep missing it! Help!

Terry says

Tape makes it easier to remove excess. Nice post.

Gil lhotka says

I often use either toothpicks in the holes or a small drill bit

Capt Hack says

toss a toothpick or clean a drill bit? Humm!

Steve Burke says

I’ve switched over to butyl tape…no “goop” to deal with.

Alex Tarlecky says

Why not just use butyl rubber? Much cleaner and it stays flexible/grippy forever.

Mark Sierakowski says

Oh dear.

I put the Sealant on the fitting. Just a bit more then required. Not over the holes, but around them. Then I can hold the fitting off the deck until the bolts are through. This may be a two man job. Lower the job onto the deck, wait for the sealant to go off before tightening fully.

Am I doing it wrong? Seems to work.

The Boat Galley says

There are a variety of ways to do things. On our boat, the nonskid has deep groves that we have to work the sealant down into.

Rick Bruser says

Awl righty then!

Doug Treff says

Use butyl tape and avoid this problem altogether.