To paraphrase one of my favorite Fatty Goodlander columns, “It’s not a question of will anything break out there, but whether I’ll be able to fix it, to handle it.” – Cruising World, January 2006, page 30.

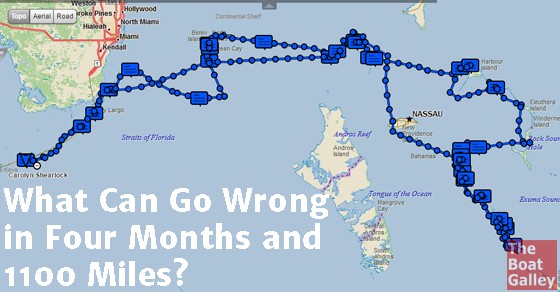

As we left for the Bahamas, a new cruiser in the mooring field at Boot Key Harbor (whose name, unfortunately, I didn’t write down) asked us to keep a list of “stuff that broke” while we were in the Bahamas.

He’d always heard that cruising was “fixing your boat in exotic places” and wanted to know not specifically what he might encounter on his own trip to the Bahamas this winter, but a general look at what could happen. While he’d read many blogs that periodically discussed fixing various things, he was interested in more of a laundry list of all stuff . . . not just the big items.

The purpose isn’t to discourage new cruisers or potential cruisers, but rather to show that yes, problems happen but most are pretty simple to deal with and don’t have to derail your cruising plans. Most of these took less than an hour to fix (at least temporarily). Only one delayed us by more than a day. We had a great time and aren’t complaining at all!

So here it is . . . along with a quick description of how we dealt with each item. From our years of cruising, I’d say it’s a pretty typical list in terms of the number and severity of items for that amount of time.

Huge quantities of water in fuel – The day after we checked into the Bahamas we headed across the Banks and, a few hours into our trip, switched fuel tanks as one was almost empty. We discovered that the fuel in the second tank was seriously contaminated. There was very little wind, so Dave just kept changing Racors as we limped 20 miles back to a protected anchorage. Discovered that the o-ring on the deck fill for that fuel tank had microscopic cracks in it, allowing gallons of rain water and deck washes into the fuel tank. Pumped out all the bad fuel and disposed of properly, bought new fuel, bought replacement Racors, taped over the fill caps so that water could not enter tank. Upon return to US, replaced o-rings and now carry spares.

This was our largest problem both in terms of time and cost, taking several days to fully sort out (thereby losing a weather window to cross the banks), two days in a marina, 5 new Racors at $38 each in the Bahamas and 15 gallons of diesel fuel that had to be disposed of (it was too contaminated with water to filter and use).

Hydraulic cylinder on drive leg – We have a drive leg that can be lifted out of the water with a hydraulic lift when anchor or sailing. It began failing (the drive leg would slowly lower over a period of hours as hydraulic fluid seeped out past a bad seal) and at first we could simply add more hydraulic fluid to replace what was leaking out. Near the end of our time in the Bahamas, got to the point where it leaked so badly that it wouldn’t lift at all.

It was not a major problem, other than being a drag and slowing us down by 1/2 to 1 knot when sailing. Upon return to US, Dave removed the hydraulic cylinder and made sure it could be taken apart (parts hadn’t corroded together), then I ordered a rebuild kit from the UK and Dave rebuilt it and reinstalled (rebuild kit cost about $27 versus $350 for a new cylinder). Got a second rebuild kit as a spare in case we have a problem again. Dave is also devising a way to block the leg up when underway so as to take the stress off the cylinder and the seals.

Medicine cabinet latch – A tiny spring in the latch stuck and the door wouldn’t stay shut, which meant that things fell out of the cabinet underway or even at anchor. Short term solution (the day it happened . . . underway) was to use a couple layers of toilet paper in the latch to give the two parts a tighter fit. Longer term, Dave was able to remove the latch and disassemble it with the aid of PB Blaster, clean it, lubricate it and reinstall it. We have also bought a spare.

Alternator belt – A few minutes after starting the engine one day, the high temperature alarm shrieked. I immediately shut the engine down and Dave opened the engine compartment and saw the broken alternator belt. On our boat, like many, the alternator belt drives the cooling water pump as well so when it had broken there was no coolant circulating. We had a spare belt, so it was a fairly simple fix. We had a second (used but still serviceable) spare with us, so we waited until we were back in the US to get another (new) spare.

Propane tank – When our first propane tank was empty and we switched to our spare, we soon discovered that it had a bad fitting and that most of the propane had leaked out without our realizing it. We had cold meals for a few days until we got our good tank refilled at Staniel Cay. NOTE: We also had several 1 pound propane canisters for the grill and could have done our cooking that way – it was simply very hot and eating cold meals was not a hardship!

USB cords – Our phones, tablet, MP3 player, speaker, several lights and more all recharge using micro USB cords. We had several of the cords die on us over the summer, either by breaking or by the plug becoming loose and not making a good connection. Luckily, we had quite a few extra cords. I’m buying more spares to have on hand – I’m sure that the motion of the boat contributed to the problems, although they don’t last forever ashore, either.

Chain grabber latch – The gate latch on the chain grabber for our anchor bridle broke – a little plastic piece. We used duct tape over the gate while in the Bahamas, and then got a free replacement (and a spare) once we returned to the US. Mantus offered to send replacements to the Bahamas, but since we weren’t staying anywhere very long, we said to wait until we returned to the US.

Tiny hose on outboard – One day, our outboard ran erratically and stalled several times as we went ashore. As we finally approached the seawall, a local guy pointed out that a bit of fuel was dripping from the back of the motor. Dave removed the cover and saw a tiny hose (about 1/8” diameter) had come loose. He pushed it back on its tiny hose barb and all was well.

Outboard fuel hose – One day, after snorkeling Thunderball Grotto, we could not get the dinghy motor to start. Actually, it would start and then die with a few seconds. It seemed like a fuel starvation issue to us and sure enough, we discovered a crack in the fuel hose. We had a bit of Rescue Tape with us and were able to make a temporary patch to get back to Barefoot Gal, where we had spare fuel hose and could replace all the hose. NOTE: We’d bought a new-to-us dinghy right before leaving Marathon and had noticed that it had brand new fuel hose . . . the same type of fuel hose that had given us fits on our previous dinghy. So we’d made sure to have good replacement hose and all the fittings with us.

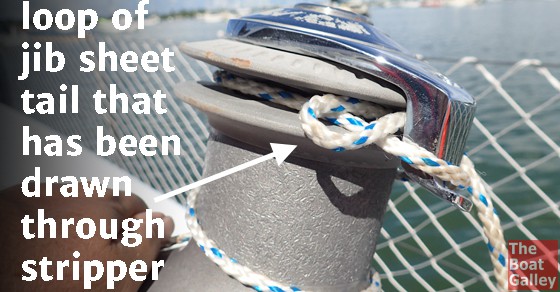

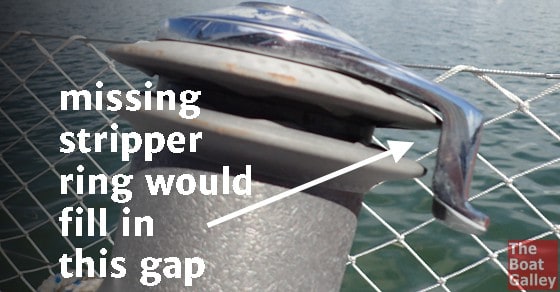

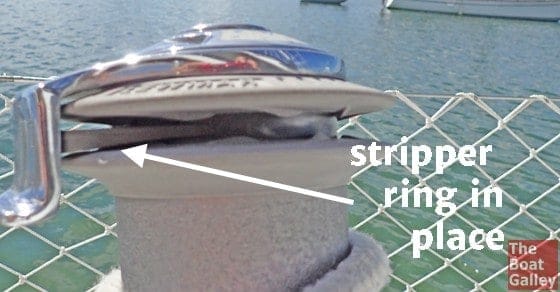

Winch stripper jam – Our starboard self-tailing winch had a tendency for the tail to double up and pass under the stripper arm, effectively binding up the winch so that the jib sheet couldn’t be winched in further nor released (what’s known as a stripper jam). In a blow, it’s as bad as an override to clear . . . and as dangerous (when all else fails, yes, you can cut the jib sheet . . . which creates another set of problems and you still have an unusable winch). Upon examination, it appeared that the little nylon part that goes under the stripper arm (specifically to prevent this) had broken off.

Temporary fix was to ALWAYS hold the tail away from the stripper (yes, it was my screw-up on this when it was blowing 25 that taught us how awful it could be to clear). Permanent fix after coming back to the US: get a new stripper ring and install it. This may take the prize for the most oddly named boat part I’ve ever bought. [TIP: don’t just Google for “stripper ring” or “winch stripper ring” (it will autocorrect “winch” to “wench”) but use the brand of winch — “Lewmar Stripper Ring” – for best results!]

Since neither one of us had ever heard of a stripper jam before this, here are some photos (note that I mocked up the jam using smaller line that I could get out of the self-tailer . . . I wasn’t about to create another jam just for a photo!).

Light switches – We have reading lamps in the bedroom and the switches are starting to fail on them so that they often won’t turn on. Immediate solution was to use the (very bright) overhead light. Attempts to clean the contacts and so forth haven’t worked, and now we’re looking for replacement switches that are the right size.

Watermaker not producing good water – One day the watermaker was making good water, testing at a little under 250 ppm. The next day when we started it up, it was over 1700 ppm. YIKES! What happened overnight? Getting out the troubleshooting guide and also consulting one online, the most likely culprit was an air leak in a hose connection before the high pressure pump. None were obvious, but when Dave started at the thru-hull and tried to tighten each hose clamp, he found one that was just a teeny tiny bit loose. Tightened it up and we were suddenly making great water again.

Dinghy oars – When we got that new-to-us dinghy, it never occurred to us to make sure the oars fit in the oarlocks. We learned this when we wanted to go up a “no motors allowed” creek on Shroud Cay this summer. Used the oars as paddles that day. Now trying to find a used set of the correct pieces to go on the oars . . .

Flies in compost – We got a fly infestation in our composting head. When we first noticed a few flies, we increased the amount of diatomaceous earth we were using – this would supposedly get rid of the flies. It didn’t. We cleaned out the compost bin and put in new compost, and the flies were back within a few days. So we bought a better selection of brushes to reach the nooks and crannies and several cans of fly spray. We emptied the compost again and this time, REALLY cleaned out the bin and sprayed it heavily with fly spray and then put fresh compost in. No more problems. (NOTE: While this was a nasty job, it was no worse than changing the joker valve on a conventional marine head.)

Toilet fan – The composting toilet has a fan on the side of the compost bin. We removed it when we were cleaning the bin so that it wouldn’t be damaged by water . . . but we managed to break the very thin power wires to it (this is a small fan typically used in laptop computers). Because of the design, they couldn’t be reattached. So we hooked up the vent hose from the toilet to our solar vent, using some duct tape to hold them together, as the local hardware hadn’t had any PVC fittings that would do the job. The solar fan didn’t move as much air as the original fan, but it was a lot better than nothing. Upon our return to the US, we got a replacement fan from Nature’s Head and several spares – all free.

Ants – We got an ant infestation. We’re not quite sure if it was from a marina stop or if we brought the first few aboard with some provisions. The traps and spray that we had with us and that we bought in the Bahamas did little to deter them. Back in the US, I bought four packages (24 bait stations!) of the gel baits by Maggie’s Farm and a package of Advion Ant Control (gel in a syringe to put in cracks). It took about 10 days, but they seem to be gone. I’m now taking the good stuff with us.

Starboard lazy jack – One of the lines in our starboard lazy jack began to disintegrate. We replaced it with some spare line.

Leaking Coke can – A can of Coke developed a pinhole leak and sprayed Coke all over the bin it was stored in. Luckily it was diet, so no sticky sugar. This is exactly why I store drink cans in bins – I simply removed the cans, washed them and the bin, discarded the bad can and all was well.

Freezer door – The little plastic hinges on the freezer door broke off. This was the second time the hinges broke and while Isotherm replaced the door under warranty the first time, I didn’t pursue a claim the second time as the design is just plain bad. Even the tiniest bit of ice buildup in the hinge area will break it – this happened just 2 days after defrosting the refrigerator, so there was not excessive buildup. I used the door and created a “hinge” out of duct tape that hopefully won’t be bothered by a little ice. We’ll see how it goes.

Centerboard line – Our boat has a centerboard in each hull. The boards float up into the slots and a line winds around a hub, turned by a winch handle, to lower them. If the hub is turned the other way, the line holds the board tightly in the slot when raised so it doesn’t rattle. The starboard line broke and investigation showed that it had been run incorrectly by someone in the past causing it to chafe through.

Our boat is designated a Gemini 105M, but we have some features that were being developed for the 105MC which came out the year after ours was built. The centerboard is one of those things – and luckily, we have both the 105M and 105MC Owner’s Manuals aboard. We could see how the line was supposed to be run, and we had spare line of the right size. But since (1) the line was broken and (2) it was run incorrectly, we couldn’t just use the old line as a messenger for the new. Dave’s hands were too large to fit in the slot, but between my smaller hands, a piece of wire shaped into a crochet hook, a small flashlight hung on a string to get light to the work area (and a lot of good “sailor words”), we managed to get a new one run in about three hours. We were pretty happy about this as several people had said that the only way to replace a broken line was to haul out and remove the centerboard.

Solar vent stopped working – Just last spring we replaced the broken solar vents that had been on Barefoot Gal when we bought her. Not three months later, one stopped working. Past experience told us it was probably a dead rechargeable battery, and we had replacements on board. Problem solved!

Toaster screen – I love my GSI folding toaster, but after several years of heavy use, the screen on the bottom was just disintegrating. I wouldn’t call it a flaw in the product – putting thin screen over a flame day after day is bound to cause a problem after several years. The screen evens the heat out so that bread toasts uniformly . . . and as it wore away, I had to be extra careful not to burn our toast. I couldn’t get stainless screen in the Bahamas and I knew that regular steel screen would rust away in no time. Returning to the US, I was able to order a replacement screen.

Engine vibration – Heading across the Banks from the Berries to the Bimini chain, we began feeling a slight vibration in the engine around 2800 RPM. We slowed down to 2600 and the vibration stopped (there was light wind; if it got worse, we could sail but we’d end up spending another night on the Banks). We think the vibration probably caused the “funny buzzing noise” below.

Investigating, Dave found one of the motor mount nuts loose. He tightened things up as best he could and we ran at lower RPMs the remainder of the trip back to Marathon. In Marathon, we hired a mechanic to realign the engine and tighten the motor mounts, and Dave learned how to do it should we have a problem in the future.

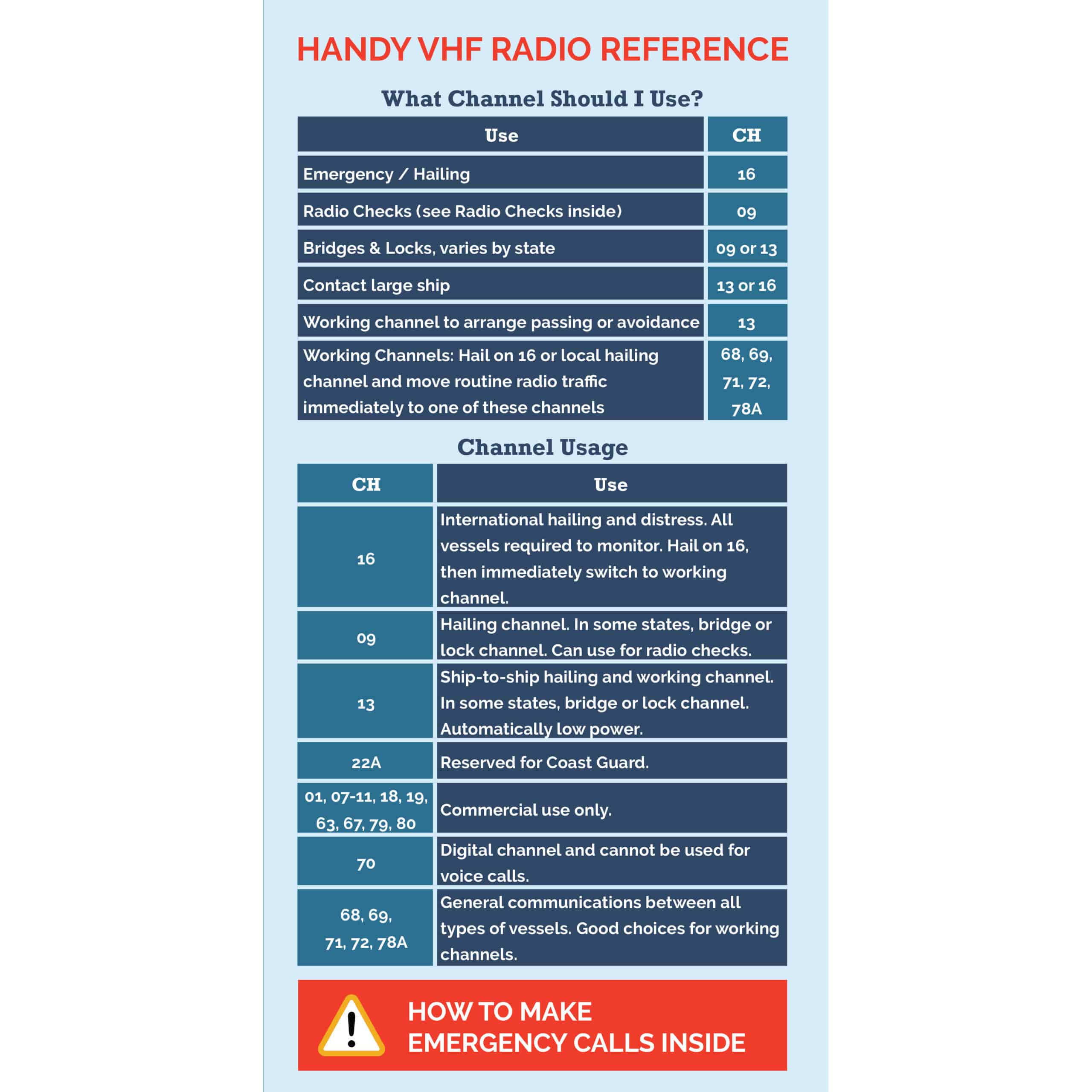

Funny buzzing noise – A little later that day heading to Gun Cay cut, we heard a noise that sounded like static-y Morse Code. At first we thought it was coming from the VHF, but then realized it was originating in our instrument panel. That’s where our alarm buzzer is, but it didn’t sound remotely like either the high temperature or oil pressure alarm, and all the gauges were showing normal. Dave finally got the bright idea to check the wiring connections on the engine and sure enough, the wire for the oil pressure alarm was a little loose in the plug. He pushed it back in securely and the noise stopped.

Diesel fuel pump – Even later that same day as we were approaching Gun Cay cut to leave the Bahamas, our diesel engine became a little erratic and sounded like perhaps we had a clogged Racor. We switched Racors, ran at lower RPMs, raised the main so that we would have steerage if the engine died, and I even plotted a course to a different cut that we could sail through if necessary. The engine continued to chug away and we came through the cut to realize that it was Labor Day weekend and every boat from Miami was in Bimini! We wove around the megayachts and found a spot to anchor.

Dave drained the Racors and found no sign of contamination, so the next morning he changed the “bad” one. Afterwards, when we went to purge the air from the system, fuel partially filled the Racor bowl and then stopped. And we couldn’t hear the distinctive “clicking” of the fuel pump. Yes, the fuel pump had died. Apparently it had been having problems the day before when we thought we had a clogged Racor. We were very, very lucky that it hadn’t failed as we’d motored between boats in the anchorage – although we had left the main up until we were anchored “just in case.”

We had a spare fuel pump with us and installed the new one. Back in the US, we bought another spare.

Aquabot – Labor Day weekend at Gun Cay, as we were replacing the diesel fuel pump, a cigarette boat near us took off for Miami. We were rocked with a monster wake and almost no warning. I grabbed up the tools nearby but couldn’t grab the Aquabot on the galley counter and it went flying. The top pump handle broke off, or actually the piston broke off right where the handle attached to it. Short term solution was to use our second Aquabot, or I could have rinsed dishes a number of other ways although I would have used more water. Upon return to the US, I was delighted to find out that I could buy the part I needed and not a whole new Aquabot!

So, while we did have stuff break, we fixed or otherwise dealt with all of it. And that’s one of the things I love about cruising: becoming more and more self-sufficient. Our first year out, we got a lot of help and asked a ton of questions. Each year, we’ve needed less and less help. It’s a good feeling!

Quickly find anchorages, services, bridges, and more with our topic-focused, easy-to-use waterproof guides. Covering the ICW, Bahamas, Florida, and Chesapeake.

Explore All Guides

Carolyn Shearlock has lived aboard full-time for 17 years, splitting her time between a Tayana 37 monohull and a Gemini 105 catamaran. She’s cruised over 14,000 miles, from Pacific Mexico and Central America to Florida and the Bahamas, gaining firsthand experience with the joys and challenges of life on the water.

Through The Boat Galley, Carolyn has helped thousands of people explore, prepare for, and enjoy life afloat. She shares her expertise as an instructor at Cruisers University, in leading boating publications, and through her bestselling book, The Boat Galley Cookbook. She is passionate about helping others embark on their liveaboard journey—making life on the water simpler, safer, and more enjoyable.

Mark Tilley says

I presume you’ve tried WD40 on a Q-tip on the light switches. My first thought on the boat had always been to try and polish corrosion off, but after soaking some frozen padlocks a couple days in WD40 I remembered what a great solution it is for corrosion too. We used it on a Q-tip later to clean up a really nasty green 12V outlet in the cockpit after we had taken on some salt water during heavy weather and it’s almost as good as new.

Tony Gariepy says

Excellent article, what can really happen, and what you can overcome!

The Boat Galley says

Thanks! The big things are having spares, tools, owner’s manuals . . . and an internet connection is handy, too — but we try to have info on board in case we don’t have a connection.

Jan Bogart says

Or four minutes? lol

Trish & Bart says

As always, great information. Thanks for sharing!

Tracie Turner Joiner says

Chris Morton

Mark Sierakowski says

Cruising: fixing your boat in exotic locations.

Reggie Good says

I also had the broken wire to the composting head issue. A computer repair shop in Marsh Harbor had a used fan from some piece of electrical equipment which he gave to me, same size as the one in my Nature’s Head. When I returned to the US, Nature’s Head sent me replacements.

The fan hangs by those tiny wires when removed from the head to service the air filter. Also, the solder joint seems to be subject to corrosion. I treated the connection points of the new fans with anti corrosion spray, then mounted the fan into the fan cover and sealed around it with calking/adhesive. Now the fan and housing are one unit and neither the housing nor the fan can hang on the wires.

Evelyn says

I added a couple of notes in our “to-do” book from this article. Very informative, Caroline, thanks.

Rosalind Franks says

Great article!

Tania Diaz says

Marek, you taking notes?

Donna says

Thanks – I also added some items to my to-do and to-buy lists! One question – what is an Aquabot?

Carolyn Shearlock says

An Aquabot is a small, handheld tank sprayer that is perfect for rinsing dishes — uses a LOT less water than other methods I’ve tried. Read more about it: Aquabot

MARK PEARCE says

I also need a rebuild kit for my sonic outdrive on my 105M. Could you pass the contact info or website please? Thank you. I love your well documented blog, it’s the BEST!

Carolyn Shearlock says

Here’s the parts list — contact info for Sillette Sonic is on it. No online ordering — you have to do it by email or phone (they’re in the UK, so a Skype call is the cheapest way to do it).

https://www.sillette.co.uk/documents/sillette_sonic_parts_list_000.pdf

Rick Hayes says

Also remember to be check the spares you purchased to be sure they are the correct size etc. Don’t store them away with the assumption that they will fit or work properly when needed.