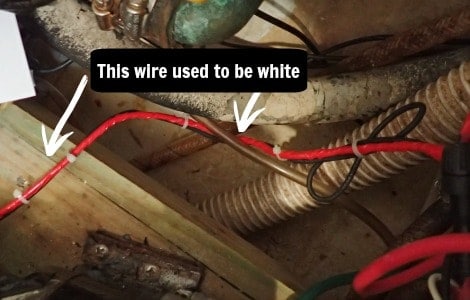

In general, Barefoot Gal‘s 12-volt wiring uses red for the positive and black for the negative. But as we’ve been doing work on various components of the electrical system, we’ve also come across white (both positive and negative), green, yellow, gray and even found one place where black was used on the positive side. On a few occasions, a single wiring run would change colors several times.

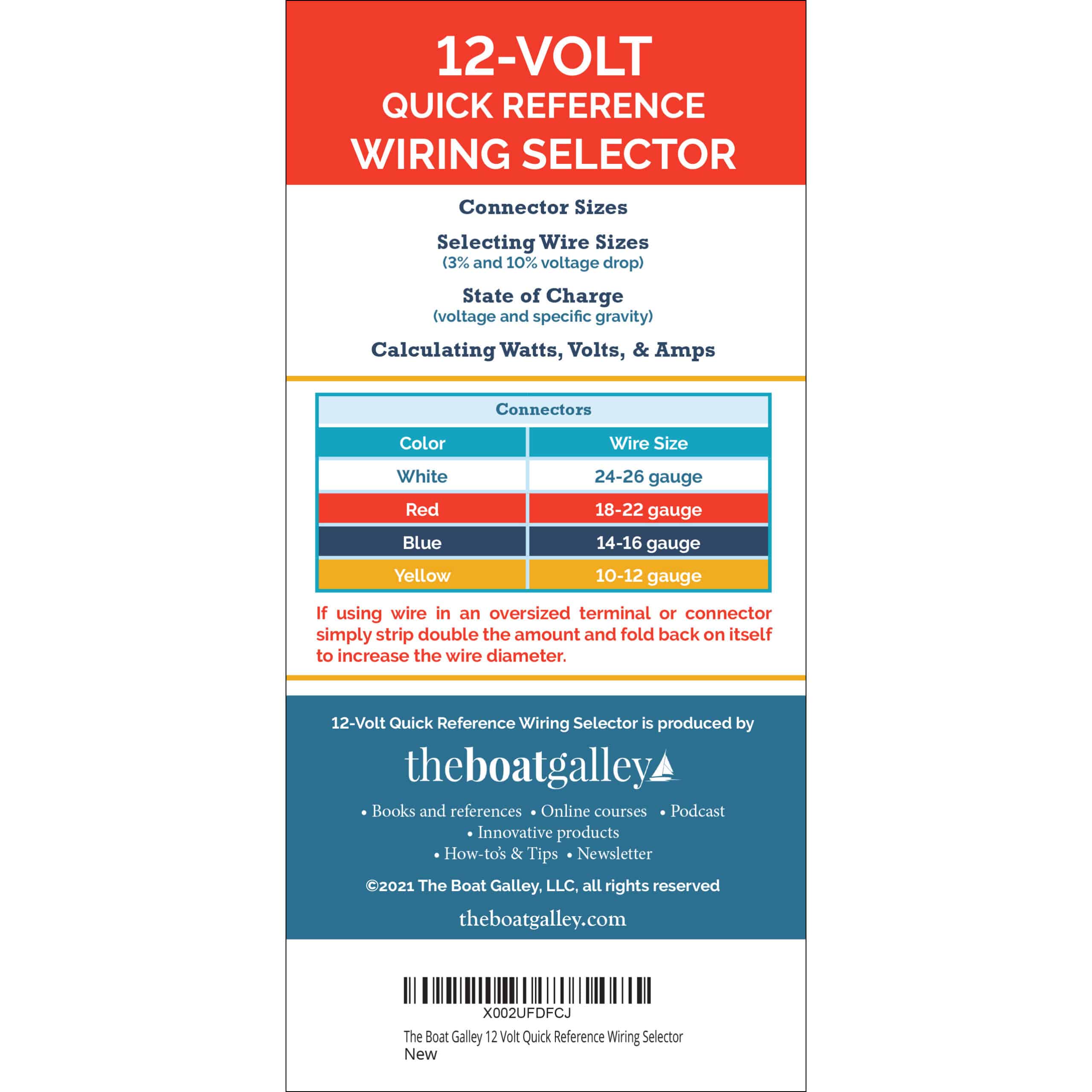

NOTE: All these colors do have particular meanings in a 12 volt system. Jamestown Distributors has a good list of color conventions. What I’m talking about is incorrect use of these colors.

Apparently, some people working on the boat had simply used whatever piece of wire they could lay their hands on that was the right size. YIKES! It certainly has made tracing wires, well, interesting. Future troubleshooting might be even more problematic.

One option would have been to rewire the strangely colored circuits. But that would have been expensive and time-consuming. Plus, things worked well the way they were wired (one of Dave’s favorite sayings is “if it ain’t broke, don’t fix it”).

So we opted for the simpler — much simpler — solution: a few rolls of red and black electrical tape. Whenever we trace a circuit and find a funny color, we wrap the wire in the correct color (leaving the connectors un-taped so we can see any problems developing).

We use a lot of cheap black electrical tape on the boat for non-electrical temporary things. But for this purpose, we bought “good” electrical color-coding tape.

While you can get it at West Marine and other specialty stores, it’s a lot cheaper to buy at home improvement stores such as Lowe’s and Home Depot. Here in the Florida Keys, it was almost exactly half the price at Home Depot as the exact same tape was at West Marine.

Carolyn Shearlock has lived aboard full-time for 17 years, splitting her time between a Tayana 37 monohull and a Gemini 105 catamaran. She’s cruised over 14,000 miles, from Pacific Mexico and Central America to Florida and the Bahamas, gaining firsthand experience with the joys and challenges of life on the water.

Through The Boat Galley, Carolyn has helped thousands of people explore, prepare for, and enjoy life afloat. She shares her expertise as an instructor at Cruisers University, in leading boating publications, and through her bestselling book, The Boat Galley Cookbook. She is passionate about helping others embark on their liveaboard journey—making life on the water simpler, safer, and more enjoyable.

Your VHF can do so much! Learn how to use ALL its features for just $39:

Dave Skolnick says

Note that new ABYC standards are for yellow 12VDC negative to avoid confusion between 12VDC negative and 117VAC hot.

Kit Russell Harrison says

This might be useful in the camper’s wiring?

Court Crosby says

It’s a lot quicker and easier to just wrap the correct color around the wire near each end.

Pete says

It would a lot easier to tape each end but in bad lighting and or foul conditions it would be much easier to trace the line if it was the same colour. There are also wire identifying tags that are numbered and can be purchased online but I like keeping it simple and economical.

Carolyn Shearlock says

You said it! My thoughts exactly.

Chip Lawson says

Carolyn

The only concern I would have with your tape solution is that after a while inexpensive electrical tape begins to deteriorate(can be within a year, particularly in a hot engine compartment) and you end up with a gooey, sticky mess and the tape will fall off and spread the goo elsewhere. A better solution might be to put longish sections of the correct color heat-shrink tubing at the ends of the wire at the crimp fitting and wherever there are splices or color changes. The heat shrink has a couple of benefits besides the color coding. It is nearly indestructible and will strengthen the wire-to-connector joint. And if you use adhesive lined heat shrink it will help protect the joint from corrosion and failure.

Chip

Ralph says

I don’t know how this would hold up on a boat, but worth a test try would be: paint the wire in the correct color of finger nail polish (or even a stripe of enamel paint).

Susie says

When our boat was made the builder took a no expense spared approach (they subsequently went bankrupt but that is another story) and labelled each end of every wire and pipe. It’s a practise that subsequent owners including ourselves have continued. Each and every wire is therefore easy to identify even if the wire itself is not necessarily the correct colour. It is perhaps time consuming to start from scratch but you could do this as and when so that eventually most wires would be labelled. Plastic tags last longer than sticky labels if you are sailing anywhere warm!

Louise Stanley says

Always something interesting in your posts..and useful too.

Diana K Weigel says

Just in time since we are trying to sort out the mess on out 30 year old boat!

Nessa Magee says

Geoff Crowther not always as they seem ? Remember doing the light in cockpit ?

Pamela Harwood says

As we are rewiring and replumbing the entire vessel, Hugh is using a fine black Sharpie on the wide white marine plastic covering of the red and yellow-coated wires to write what they are for. Battery cables, red and yellow, are big enough to write directly on them.

Meghan Thornton says

Dealing with my heritage spaghetti wiring was what I did all day yesterday while nursing a sinus infection!

Gillian Lisa Johnston says

Got this to look forward to!

Lol.

Gillian Lisa Johnston says

Hopefully without the sinus infection though.

Dawn Read says

Lucky, good idea until we hit the lottery and completely start over.

Great article.

Gillian Lisa Johnston says

This is one of the jobs to do while Moggie is out of the water! Previous owners have added wires, disconnected things leaving wires in place, left other items in place while just cutting wires. A fire hazard waiting to happen. I want to replace all the linings anyway as someone has installed lightweight melamine board as headliners. Easy to clean but now it’s breaking and coming off all over the place so a good time to trace the wires and renew.

Scott Doublisky says

Coming from the industrial world where they used one color wire for every and all circuits.. we used wire markers.. a notebook full of numbered strips to mark runs. ie… The bow light circuit is #5.. Everywhere there’s a connection or junction in that run you put the #5 sticker all the way back to the panel..

ErnieO says

Colored shrink tube is much cleaner than gooey tape.

Carolyn Shearlock says

Yes, but to use it you have to disconnect one end of the wire. Sometimes that isn’t so easy and thus the tape solution works better.