Running new electrical wires on a boat generally is no fun. More often than not, where they need to go is hidden in the bowels of the boat, twisting and turning.

Last summer, we installed a new refrigerator. It runs on 12 volt electricity instead of propane as the previous one did. Overall, that would make it much more efficient.

There was just one problem: we had to run new wiring for it. There wasn’t any old wiring to even use as a guide – we were going from scratch.

It didn’t seem like it would be a big deal: straight line, it would be about an 8 foot run. The way it had to run, though? About 18. And all hidden behind panels that could not be removed. There were a couple of access points in the middle but they had very tight cut outs. No way would we be able to just snake a wire from one end and expect it to come out where it should.

NOTE: Read the comments for some more great tips from readers!

Tip 1: Electrician’s Fish Tape

Electrician’s fish tape is designed for just such things. It’s a springy, semi-flexible wire tape that comes on a reel in various lengths.

Feed it from the end with the more restricted opening (hopefully you can reach to it and wiggle the end of the tape through, then push it towards the other opening. The tape is rigid enough (unlike the wiring) that it will go straight and not just ball up when it hits an obstruction. Feeding the tape is easiest with two people, one to push it and then sweep it from side to side and the other to yell “stop” when they see it in the other opening and grab it. It’s possible to do by yourself, though – it just takes a lot of going back and forth, moving the fish tape just a little at a time.

In the past, we’ve always been able to pull the new wire through by simply taping it to the fish wire and gently pulling. Not this time! The opening was tight enough that joint would be pulled apart and we’d have to feed the fish tape all over again. It only took me two failed attempts to decide there had to be a better way.

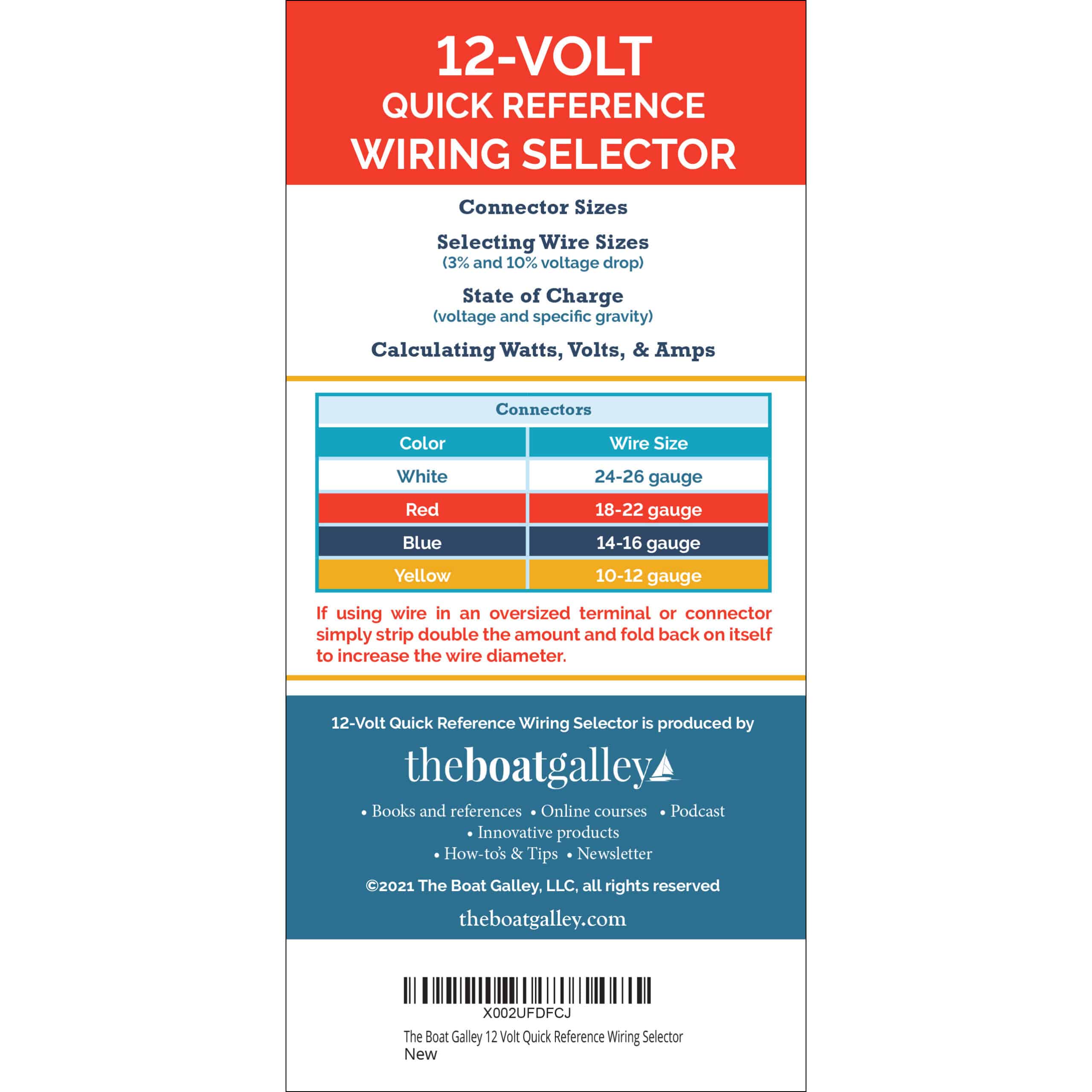

Tip 2: Crimp on a Screw Connector

I needed a connection that wouldn’t come apart even when I tugged on it to get it through the tight spots. The fish tape had a nice eye on the end; I just needed a way to attach the wire to it. First I tried stripping a section of wire and then passing it through the eye and twisting it back together and taping it. Nope, it pulled apart again.

I finally decided to sacrifice a screw connector. I crimped it onto the wire, then used a cable tie to attach it to fish tape. I put a little wrap of electrical tape over the joint so that it was nice and smooth and wouldn’t snag. It held perfectly, even with me having to tug a fair amount to get it though one blind spot. I couldn’t believe how easily it worked. After the wire was run the whole way, I just cut it off

You can see both the end of the fish tape and the screw connector I crimped to the wire in the photo above. The big thing in buying fish tape is to get one that is stiff enough to push through a narrow opening. Because they’re made of stiff metal, it can be a bit of a chore both to unwind and wind the tape. Look at it as part of the onboard fitness program!

You can get fish tape at any hardware or home improvement store . . . or on Amazon if you just want it delivered to you:

- Klein Tools Fish Tape – 4 different lengths; the end is slightly different than on ours (and I think this one is better)

On our boat, 25’ is sufficient and we’ve even used it to pull new reefing lines through the boom. If you’re running wires inside your mast, sometimes a longer fish tape is handy (sometimes you can do it with gravity; sometimes wires need some help if they have to pass through particular channels). NOTE: Fish tapes are made of mild steel (the ones made of nylon aren’t stiff enough to do the job) so it’s best to store it in a Ziploc with a dessicant pack to remove moisture from the air. If you have a microwave, Dry & Dry work well as you can recharge them over and over.

Carolyn Shearlock has lived aboard full-time for 17 years, splitting her time between a Tayana 37 monohull and a Gemini 105 catamaran. She’s cruised over 14,000 miles, from Pacific Mexico and Central America to Florida and the Bahamas, gaining firsthand experience with the joys and challenges of life on the water.

Through The Boat Galley, Carolyn has helped thousands of people explore, prepare for, and enjoy life afloat. She shares her expertise as an instructor at Cruisers University, in leading boating publications, and through her bestselling book, The Boat Galley Cookbook. She is passionate about helping others embark on their liveaboard journey—making life on the water simpler, safer, and more enjoyable.

Your VHF can do so much! Learn how to use ALL its features for just $39:

Tony says

When you are running wire, you can attach a thin nylon line along with your wire and drag it through your wire run. The next time you need to run wire, just attach it to the nylon!

Bill Culbertson says

Carolyn,

Love the screw-connector/cable-tie idea. An alternative to traditional fish tape is a set of fiberglass rods. Centech makes a set using 33″ rods but on the boat I use their set of 12″ rods. Amazon has them here: http://amzn.to/1UY1BDd

-bill culbertson

“Harmony”

Brian says

Really cheap at harbor freight. I bought the long set for home and the short set which expands to over 11 feet for the Boat. They are in 1’ increments.

Liz Aloha says

Two more things to try when you’re having trouble running a wire:

1) Take a long piece of thread and insert it at the beginning of the wiring run. Secure one end and leave the other end free. Put the hand nozzle of your ShopVac at the far end of the wiring run and suck the free end of the thread through. Use the thread as a leader to pull a stronger string through. Use the string to pull the wire through. Note that if the thread is light weight enough, the ShopVac will suck it through even if you can’t make a vacuum-seal at the far end of the run…you just need enough auction to get an air current flowing through there.

2) Try spraying some sail-track lubricant or silicone lubricant on the exterior of things you’re having trouble shoving through: the fish itself, the wire, any leader strings, etc.

Pamela Douglas Webster says

Easier, but still not a job I’m looking forward to. 🙂

Mike Webster

Allan says

running wires is always better than running pipes, IMHO

Raquel Hernandez says

Brian Liddy

Will Klein says

Armour All will make the plastic coating on the wire slippery and let it slide through more easily.

Paul says

I’m not a big fan of metal fish tapes on the boat, corrosion the biggest issue as mentioned.

I have had to run both new electrical wires and hoses (installed Air Conditioning) and found the best tool to feed the lines was a Fiberglass Multi part rod similar to the one used in Deflecto Dryer Duct Cleaning Kit, 12′ (amazon about $20) Easily stored and the kit I purchased had a end piece with a hole in it that I could secure a tie to the hose/wire.

Totally agree with the idea of a Messenger line that can be used for future runs.

Paul

Brian says

I run an extra pull string every time I pull a wire on the boat. Never know when you will need it.

Stuart & Virginia says

I use a length of plastic shroud cover (which are split all down one side). If the wire is small enough in diameter, open the split and insert a few inches of wire. That is usually tight enough to hold the wire but a tight wrap of electrical tape will also help. I pre-fish the shroud cover to find the best route for the wire. Even if the wire is larger than the diameter of the shroud cover, the split will still grip the electrical wire quite well…

Terry says

Great idea.

If you want to know our pro secret….get some 10mm by 3mm for 99% of the world or 3/4 inch by an 1/8th for the other 1% (joke)

It’s plastic epansion joint holder for large wooden sections of board in houses….ask any electrician. It is solid side to side, yet flexible around bends.

A small hole in one end allows you to push it through, connect cable and pull it back. I use it all the time. (Unless charging by the hour) 🙂

like i said, this is a pro secret….so don’t tell anyone.

Michelle Rene says

Great info and appreciate the comments of your followers. It’s always a hard job, these tips will make it less frustrating

Anonymous says

Good tip.

Steve Brigham says

Tony, while in theory your idea sounds very good, however it depends on what you mean by thin. To thin and you have essentially installed a knife blade because as you pull on it. if it is under tension and riding on the insulation of another wire it will cut it. The thinnest I would recommend is 1/8 inch. even then I have had it chafe wires.

Ted Broom says

Old coated life line or shrouds also work good. They are SS so no rust and will roll up for storage. Crimp a screw connector and it’s ready to go.

Ted

Peter Bonesio says

Upgrading electronics the past few weeks, lead me to use my fish tape to run new transducer and other wire for other upgraded electronics on my bass boat. After many attemps (by myself), he fish tape kept getting snagged on whatever is in the 8′ run from the stern to the console. I though of using a dispensing end from a standard tube of caulk (sacrified a $1.49 new tube), cutting it close to the tube leaving a 3 – 4 inch tappered nozzel and don’t cut the tip off. Inserted the end of the fish tape and securing the nozzel aft end with electrical tape. Sprayed a little WD40 on the tip and first try without any snags, the nozzel showed up in the access door to the console. Then running the wires became a breeze from then on.

David NORMAN says

To run electrical wires through a maze of other wires and small gaps i use an 8mm dia length of house hold irrigation conduit normally used for garden sprinkler systems. Just poke the conduit through and then push the cable through, it is as simple as that. This system has saved me a lot of time and energy and not to mention elevated blood pressure and the accompanying bad language.

Dave stiller says

I have been dipping the wire ends in dielectric grease before inserting them in the crimp connectors. Reduces the opportunity for corrosion and does not seem to reduce conductivity.

Harold says

I had to run a new coax cable for my antenna, I couldn’t push the cable a foot before it binded up. I poured some dish soap down the the hose they had it running through. Went and had a coffee, came back and pushed the coax through no problem…lube is the answer.