If you don’t have a full shop with a vice and so on, it can be tough to make a nice clean square cut in stainless tubing.

We’ve been working to beef up the stainless on our dinghy davits in preparation for a new, very large solar panel. We could only get the new stainless tubing in half-foot increments, plus we wanted to dry fit it and mark exactly how long it needed to be. And we were reusing one old section of tubing to make two shorter diagonal supports.

That was going to be three cuts. The squarer we could make the cuts, the more securely they’d fit into the connectors and the stronger the overall structure would be.

Here’s the best way we’ve found to do it, working in the cockpit with minimal tools. We’ve tried using the Dremel tool to cut and found that while it would work, it would take forever. And we don’t have a stainless tubing cutter (a worthwhile investment for a bigger project but note that you have to have a tubing cutter designed for stainless, such as this one on Amazon, and it still helps to mark the tube and begin the cut with a file as described below so that the cutter doesn’t wobble and spiral).

So it’s a hacksaw for us. A new blade helps a lot. A full size hacksaw would also be faster than the mini one, which is better for working in confined spaces. Alas, we don’t have space for every conceivable tool on board and it’s a compromise.

Start by dry fitting the parts as much as is possible and making a small mark where it needs to be cut. A Sharpie or a piece of tape works well to make the initial mark.

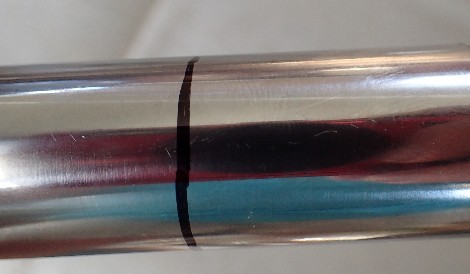

Then we mark all the way around the tube, using a carpenter’s square to keep it square. You can also use one of your fittings if you have the type that encircles the tubing. We use a Sharpie to make the mark.

Then we mark all the way around the tube, using a carpenter’s square to keep it square. You can also use one of your fittings if you have the type that encircles the tubing. We use a Sharpie to make the mark.

We’ve found that marking all the way around really helps in making a square cut as it gives a visual reference all through the cutting process.

Then we take a small triangle file and etch where we’ll start the cut. This is really important as it keeps the hacksaw from slipping.

Now we’re ready to hacksaw! With the blade in the groove we made with the file, we (okay, it’s Dave with me helping to hold) start slowly until we’ve got a straight line established.

As he cuts, Dave gets to a point where the tubing starts to V and bind the hacksaw. I’m usually helping to hold the tubing, and now I start holding DOWN on the outside end, but pulling UP with the hand nearer the cut. I’m not trying to actually lift the tubing, just keep it from V-ing down as Dave cuts.

Use a file to smooth the cut end.

Carolyn Shearlock has lived aboard full-time for 17 years, splitting her time between a Tayana 37 monohull and a Gemini 105 catamaran. She’s cruised over 14,000 miles, from Pacific Mexico and Central America to Florida and the Bahamas, gaining firsthand experience with the joys and challenges of life on the water.

Through The Boat Galley, Carolyn has helped thousands of people explore, prepare for, and enjoy life afloat. She shares her expertise as an instructor at Cruisers University, in leading boating publications, and through her bestselling book, The Boat Galley Cookbook. She is passionate about helping others embark on their liveaboard journey—making life on the water simpler, safer, and more enjoyable.

Your VHF can do so much! Learn how to use ALL its features for just $39:

Diana K Weigel says

Great tip

Randy Price says

We have always used just a regular old hardware store tube cutter – the cheap edition. It has always worked well. With a cheapo you just have to watch the tension. To tight and the blade will be destroyed in just a few turns around one inch tube.

The Boat Galley says

We’ve had zero luck with the cheapies — glad to hear it worked for you.

Bill Dixon says

I agree with Randy. Have used hardware store pipe cutters for years on stainless. Didn’t know there were special cutters for stainless.

Deborah Mackenzie says

Alan Mackenzie

Wally Moran says

To get a straight line around the tubing, just fold a dollar bill (or any piece of paper) around it till the edges meet. Using a carpenter’s square would be awkward.

Michael Miller says

One option is to use a cutting guide. We use then regularly to cut handlebars at my bike shop. They are small and work great. Hardware stores have them, but a local bike shop can order one for you as well.

Michael Miller says

This is a link to the cutting guide. Made in USA too!

Park Tool Cutting Guide

Lynn Kaak says

Our 35′ monohull has a full vise and full size hacksaw. They have both been used many times for many different jobs. We think there are some tools worth making space for (but we don’t have a dremel).

Carolyn Shearlock says

And see, we think a Dremel is essential. Use it for SO much stuff! Everyone has different ways of doing things — love hearing all the different approaches.

Larry Lockwood says

You can get a very cheap, plastic, miter box for about $5 at the hardware store. Seems like using that, with a full size hacksaw might also do the trick, and give you the ability to cut angles as well.

Carolyn Shearlock says

Yeah, but we just don’t have space for many more tools on board!

Michael R Miller says

We use a cutting guide used in bike shops to precision cut handlebars.

Ray Thackeray says

Any professional steel worker would cut the pipe in seconds with an angle grinder and dress the tube square on the side of the disc.

Carolyn Shearlock says

Fresh out of professional steel workers on our boat! Sure, there are all sorts of “better” ways to do it if you have different tools and/or a shop. This is how we do it with hand tools.

Bob Grener says

I saw numerous replies of people telling you how they accomplish this or why your method has faults, but I would like to say Thank You for letting me know “How you do this”. Thanks

John Forsyth says

To mark or draw a “square” cut on s.s. Tubing just take a strip of masking tape and wrap it around the tubing so that it perfectly overlaps along its outside edges—- now you have a perfect right angle mark for cutting the tubing and you don’t even have to mark it either ( you can if you want to) ..just cut alongside the edge of the masking tape…same idea as the dollar bill but cheaper ?

Chris says

Similar to John F. We just wrap a piece of straight edged paper around the tube. Super simple and super quick.