It all comes down to the fid. Simple.

We had to replace our spinnaker halyard after Hurricane Irma, and our experience with our first double-braid splice told us we didn’t want to do a second. So we called on our friends at Keys Rigging, in Marathon, Florida.

They said sure, they could do the splice. But why didn’t they teach us an easier way to do one at the same time? Sounded like a good deal to us.

The first thing they said was that standard fids are hard to use (yeah, I’ll agree). They make their own from the center strand of 1×19 rigging wire — you need a piece 18″ or so long. You can get one from the scrap pile at any rigging shop. Fold it in half and tape the ends together. Make sure that the fold is a sharp 180° turn — the closer together the two wires, the easier it will be on the second fid pass.

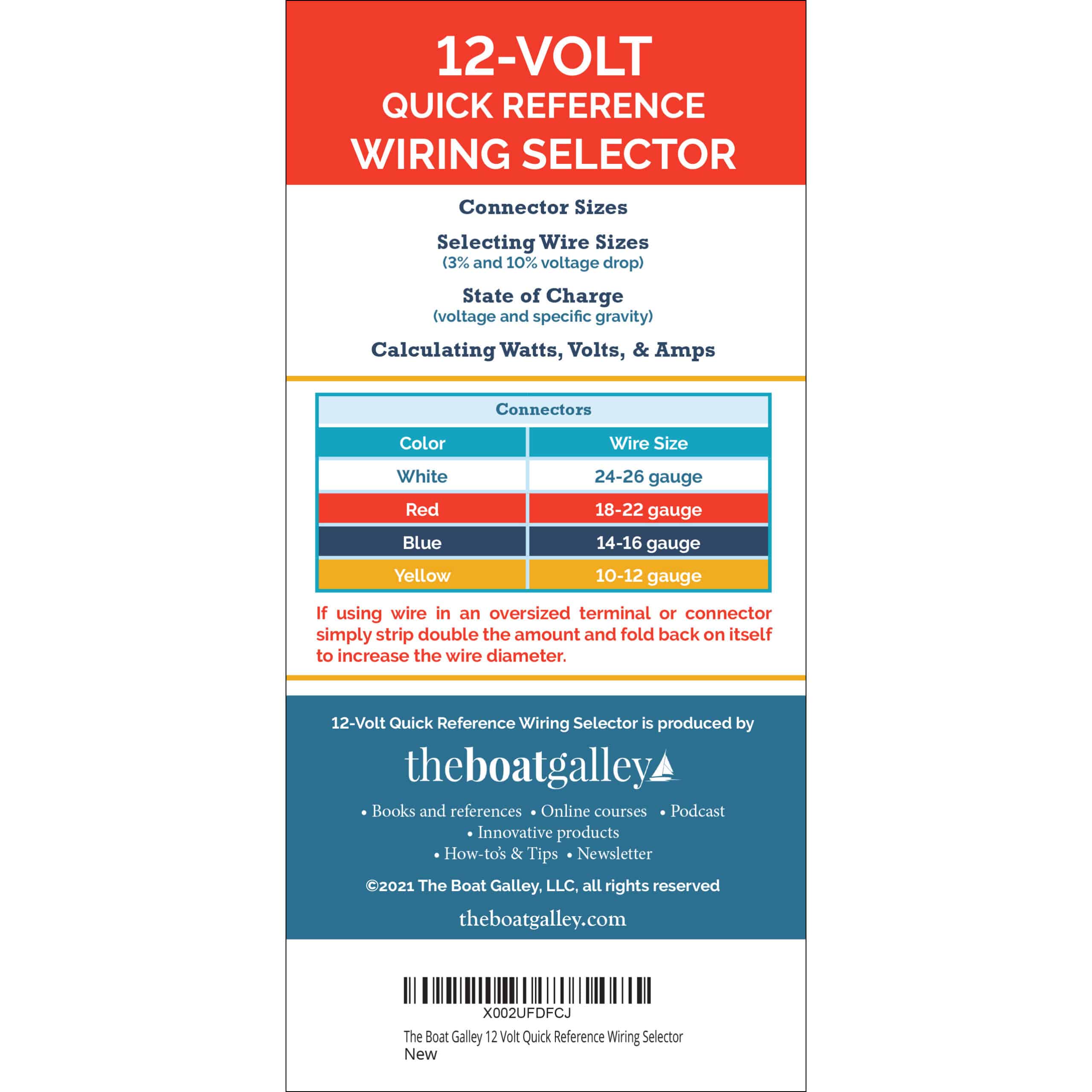

I’ll be referring to the directions given by Jamestown Distributors here for the initial measuring of the line. If you don’t have a traditonal fid (and why would you since you just made your own?), here’s a handy chart of fid lengths.

Do Step 1 and the first part of Step 2 in the Jamestown instructions, where you pull the core out of the cover. Don’t tape the ends as they suggest. Next, you’re going to taper the cover. From Mark C, go one “fleck” towards the end of the line and pull two strands of the cover out on each side of the line. Do this at every fleck to the end of the line. It’ll look something like this (you can use a needle, paper clip or even the tip of a pen or pencil to pull the strands out. Cut them all off flush with the cover.

Then make Marks 1, 2 and 3 as per the Jamestown instructions.

Put the folded end of your homemade fid into the center of the core at Mark 3 and out at Mark 2.

Thread the tapered end of the cover through the “eye” of the fid.

Pull the fid back out through Mark 3 until Mark A on the cover (the mark just above where the taper starts) is at Mark 2 of the core (letter marks are on the cover, numbers on the core). Where Mark A and Mark 2 meet is called the crossover point. It’s critical that these marks line up, so put a needle or paperclip through the cover and core at this point.

Put the fid in at Mark D and out at Mark C. Be very careful to put the fid between the cover and core and not snag either one of them (snagging either one will make it almost impossible to get the core through). Thread the loose end of the core through the eye and pull the whole fid back to Mark D until the core comes out.

This is really tough. You’re going to say something along the lines of “I thought this was an easier way to splice!” Trust me, it’s considerably harder with a traditional fid. Just keep pulling. Every so often, stop and bend the line back and forth where the tip of the fid is — this will help loosen the cover. Still, once the tip of the fid gets to the point where the cover already has the core in it, it’ll be tough. I bent my fid into an “L” so that I could stand on it while pulling.

Finish with Steps 6 and 7 from the Jamestown directions. I find that it’s best to use a cleat or winch on the boat to hold the end of the line — those are the sturdiest points on most boats.

Carolyn Shearlock has lived aboard full-time for 17 years, splitting her time between a Tayana 37 monohull and a Gemini 105 catamaran. She’s cruised over 14,000 miles, from Pacific Mexico and Central America to Florida and the Bahamas, gaining firsthand experience with the joys and challenges of life on the water.

Through The Boat Galley, Carolyn has helped thousands of people explore, prepare for, and enjoy life afloat. She shares her expertise as an instructor at Cruisers University, in leading boating publications, and through her bestselling book, The Boat Galley Cookbook. She is passionate about helping others embark on their liveaboard journey—making life on the water simpler, safer, and more enjoyable.

Your VHF can do so much! Learn how to use ALL its features for just $39:

Anonymous says

Mark

Anonymous says

Being way too cheap to buy one, I also made my own splicing needle (fid). I used the copper core of some heavy duty Cable TV wire, and epoxied it into a handle made out of the handle-ish-looking shipping spacers from our new washing machine. Works like magic.

Anonymous says

Another good source for the wire 😀

Chris says

It just moved

https://support.jamestowndistributors.com/hc/en-us/articles/360052068854-Splicing-guide-double-braid-eye-splice

Bob Petrasek says

Jamestown Distributors does not appear to have a downloadable PDF. of the instructions that you mentioned. They appear to have switched to YouTube videos. They are not clearly explained. Any other sourced that you would recommend?

Carolyn Shearlock says

Oh darn! No, I don’t have an alternate source.

David Sliwkoski says

I’ve used the Samson splicing kit, which comes with 4 or 5 fids and and a pusher. Number one don’t use the directions that come with the kit. There are a number of videos on YouTube that explain how to make the splice. I use the one from West Marine. Number two: before you start milk the cover back then pull it back into place. This will take the tension out of the cover. Once you do the splice two or three times, you will be able to splice double braid of any size in 10 to 15 minutes or less. I find it so simple that I am more likely to splice a line than tie a not.

Carolyn Shearlock says

Thanks for the tips!

Jen Fordyce says

Hi Carolyn, thank you so much for these instructions, they are so helpful. I have had a couple of goes at splicing without much luck but will to try as I am such I will get there and this info is great. The last photo shows an image that says wash white line twice before splicing, do you recommend this and is that just in cold water without soap.

Does the quality/price of the rope make a difference to how hard it is to splice. Would love any advice on this, thanks

Carolyn Shearlock says

The WASH refers to your HANDS, not the line. The photo above that shows how dirty my splice got from the dirt on my hands.

I don’t know if lower quality line is any different to splice . . . we only use high quality on our boat.

Michael Scipione says

the following instruction on burying the core, Mark C is incorrect as it is already buried in the core past the crossover. Picture shows fid correctly coming out mark A (the crossover). i also found that a cable tie in addition to the needle helps hold the crossover.

Put the fid in at Mark D and out at Mark C. Be very careful to put the fid between the cover and core and not snag either one of them (snagging either one will make it almost impossible to get the core through). Thread the loose end of the core through the eye and pull the whole fid back to Mark D until the core comes out.

Carolyn Shearlock says

Yes, snagging either the core or the cover makes it infinitely harder! Thanks for the fid info. As stated in the article, I find the wire easier than using a fid but everyone has their own preference!

Michael Scipione says

Jamestown Instructions suggest they be printed to a pdf file and saved

https://support.jamestowndistributors.com/hc/en-us/articles/360052068854-Splicing-guide-double-braid-eye-splice

and a fid length table

http://atlanticbraids.com/wp-content/uploads/2018/07/Fid-Lengths-Measurements.pdf

Col Delane says

“the center strand of 1 x 19 rigging wire” doesn’t indicate what gauge the 19 strands are, as 1 x 19 rigging comes in wire of multiple thickness.

What thickness do you recommend for the DIY fid?

Carolyn Shearlock says

I think ours was from 1/4″ wire.

Helge Tepp says

That depends on the size of the rope you want to splice. Look up for D-Splicer. You will find several cailibers there. I use these tools in all sizes and they are sturdy enough to do the job nicely. For a mooring line with an eye of 20″ you will either work the splicing as a series of going in, coming up, diving in at the same spot. Or you go for the xxl Modell, I use it all the time, so far up to a gauge of 20 mm.

Eric Feldman says

When using the wire pull fid, thread just a minimal tail (1/4”) thru the fid.

The less “tail”, the easier the pull – the difference is Amazing!

And it is surprising how well the wire fid holds a very short tail.

One more thing, according to our local rigger, DO NOT twist the wire fid while pulling – it will break.